Makerspace is a state of art additive manufacturing facility established to foster Innovations in young engineers, facilitate research and support additive manufacturing in industries. This unique facility is distinguished as a “Centre of Excellence for Additive Manufacturing” by Stratasys, India.

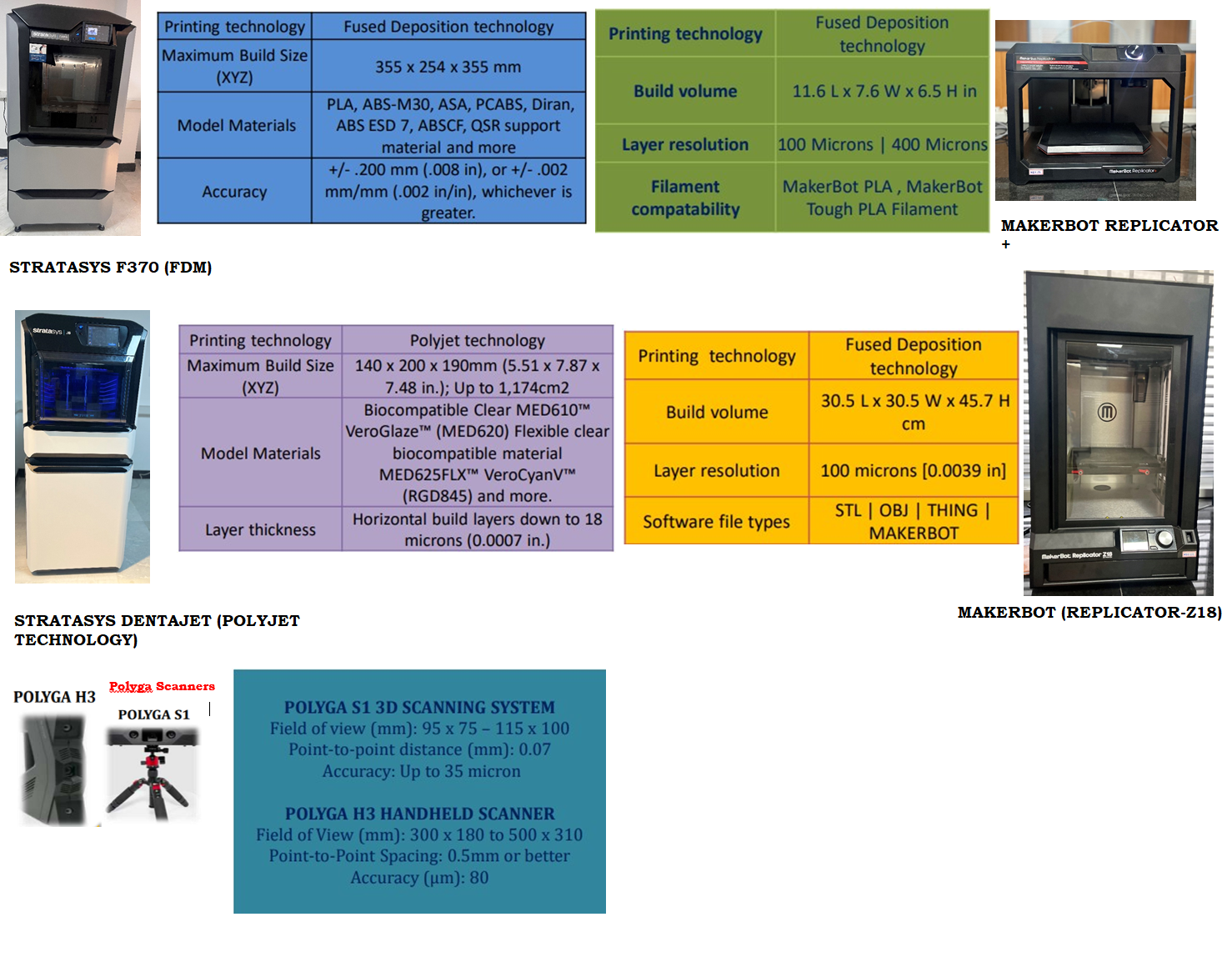

Makerspace consist of a Fablab which has F370, 5 Makerbot+ and 3 Makerbot Z18 running on Fused deposition technology, and a dentajet printer powered by polyjet technology. Makerspace also include labs for material synthesis, & testing, prototype designing and tissue engineering.

VISION

Pioneering the additive manufacturing revolution, establish an ecosystem of innovative minds and self-motivated entrepreneurs to propagate cutting edge technology.

MISSION

- Provide design and prototype solutions thereby facilitating disruptive technologies to industries, research & technological centres.

- Establish breakthrough research in biomedical and other engineering fields with industrial collaboration

- Provide workspace to innovative minds

ABOUT US

Inaugurated MAKERSPACE lab by Dr. Mariazeena Johnson, Chancellor, as a research wing of Sathyabama Centre for Advanced Studies at Sathyabama Institute of science and technology on 6th September, 2022. The management of Sathyabama Institute of science and technology has Sanctioned a magnanimous Fund of Rs. 3.0 crores for Additive Manufacturing Research activities as First Phase of Instrumentation facilities and Infrastructure.

Facilities Design lab:

Design lab is equipped with high configuration PC’s, scanners and a variety of modelling softwares. The softwares include a versatile 3D experience (dessault systemes) for design and simulation, GrabCAD, FlexScan3D etc. This facility accommodates powerful tools for 3D modelling simulations and analysis of design properties. In addition, the softwares for 3D model development of human anatomical parts from CT scan can be accessed.

Chemical processing Lab

The lab is well equipped for synthesis of an array of materials and nanocomposites for engineering and biomedical applications. The facility hosts magnetic stirrers, deep freezer (-20 ⁰C), refrigerator, hot air oven, pH meter, water bath and other equipments.

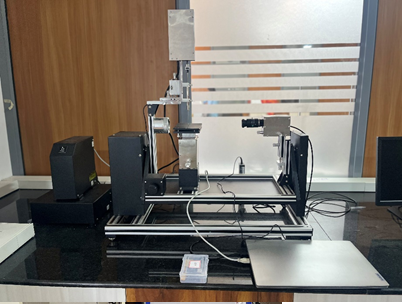

Fablab is equipped with state of art 3D printers from the pioneer in the additive manufacturing industry “Stratasys”. FabLab has F370 fused deposition printer, Dentajet polyjet printer, 5 Replicator +, and 3 Replicator Z18 printers fitted with experimental extruders. These experimental extruders facilitate researchers to print novel materials developed in lab. FabLab has a post processing facility equipped with pressurised washing system, polishing and finishing devices to provide fine finishing of printed products. In addition, one desktop 3D scanner and one handheld scanner is installed in the facility.

Material Testing Lab:

Universal Testing Machine (50KN): Mechanical stability of novel composite materials, polymers, metals and alloy can be tested. An array of tests such as tensile, compression, adhesion, pull-out, bending, and hysteresis test can be performed.

Contact angle measuring system: The contact angle measurement is to determine wettability and solid-liquid interface chemistry of the samples.

UV-Vis Spectrophotometer (Hitachi): Ultraviolet-visible (UV-Vis) spectrophotometer is a widely used technique in many areas of science ranging from bacterial culturing, drug identification, nucleic acid purity checks and quantification, quality control in the beverage industry and chemical research.

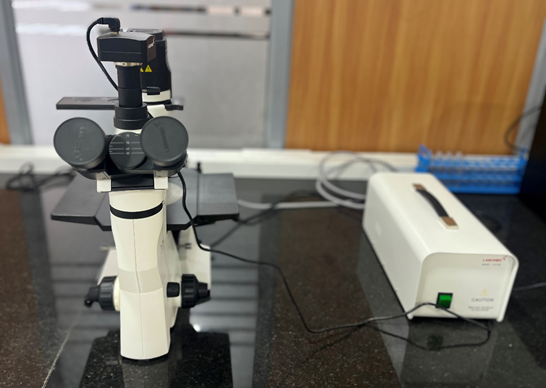

LYNX – Stereomicroscope: Stereomicroscope is used to examine, bacterial morphology, tissue sections such as surface of brains, tissue slices, or large neural structures.

TISSUE ENGINEERING LAB

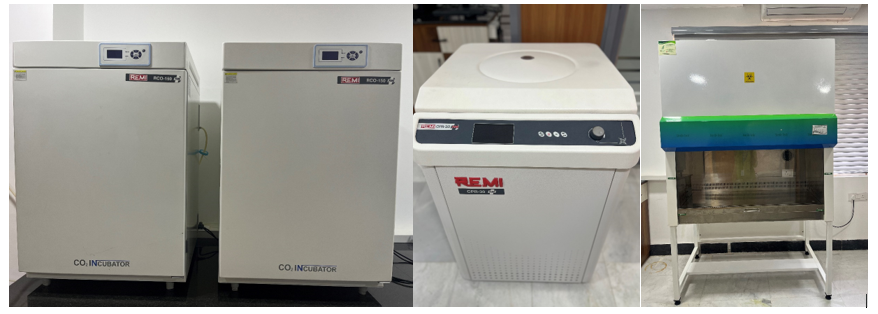

Tissue engineering lab is established to propel biomedical research. The core areas of research are bone tissue engineering, cartilage engineering, skin regeneration and menisci engineering. Drug delivery from 3D scaffolds, polymeric and proteinaceous nanoparticles, nanofiberous mats are yet another aspect of biomedical research which is being conducted. Primary cells from humans such as osteoblasts, chondrocytes, menisci cells, skin cells etc., are cultured in the facility. Cytotoxicity testing for novel materials, composites, and an array of materials used for biomedical purposes are conducted. The lab infrastructure includes CO2 incubators, inverted/ fluorescence microscope, refrigerated centrifuge, ELISA plate reader, biosafety cabinet, shaking water bath, -20°C, refrigerator and light microscope.

APPLICATIONS OF 3D PRINTERS

Additive manufacturing is the choice of technology in fabrication of prototypes, tools, parts etc., for versatile applications, in the fields of drones, automotive, robotics, aerospace and medicine. The 3D printers available in Makerspace are being utilized for the following activities.

F370/REPLICATOR+/REPLICATOR-Z18 (FDM Technology)

The state of art F370 printer is used to fabricate the models in various applications such as aerospace (aircraft interior models, landing gear assistance, miniature models, patterns for sand casting), automotive industries (headlamps housing, dashboard, door handles, brake pads, tyre/wheel rims, gear assistance, composite tooling, injection mold tooling, and production parts) and medical industry (surgery planning, implant prototypes).

DENTAJET (Polyjet Technology)

Dentajet printer is extensively used for dental applications including acrylic orthodontic devices, rigid and opaque implant models, dentures, surgical guides, soft gingival masks, indirect bonding trays, flexible gum tissues, hard materials for teeth and bone, custom impression trays, RPD framework, crown and bridge models, cardiac digital anatomy and orthopaedic digital anatomy applications.

STAFF

1. Dr. S. Manjunath, Scientist – C

2. Dr. K. Gobi Saravanan, Scientist – D

3. Dr. S. Preethi, Scientist – C,

4. Dr. Sony Varghese, Scientist – C

5. Mrs. V. Aruna, Scientific Assistant

6. Mr. S. Kathiravan, Scientific Assistant

7. Mr. Madanagopal, Scientist – C

Publications:

Thrinayan Moorthy, Mohamed Hathim B, Murali NagaMahesh C H, G. Anburaj, Shiek SSJ. Ahmed, V. Gopinath, Ganesh Munuswamy-Ramanujam, Subha Krishna Rao, Manjunath Srinivas Kamath, Journal of Drug Delivery Science and Technology, 2023, 104396, ISSN 1773-2247.

Darson, J., Thirunellai Seshadri, R., Katariya, K. Manjunath S. Kamath, et al. Scientific Reports (SpringerNature Publications) 13, 1697 (2023).

B. Renganathan, Subha Krishna Rao, Manjunath S. Kamath, K. Ajitha, A.R. Ganesan, A. Deepak, Microchemical Journal, Volume 183, 2022, 107890.

B. Renganathan, Subha Krishna Rao, Manjunath S. Kamath, A. Deepak, A.R. Ganesan, Measurement, Volume 207, 2023, 112341.

S.K. Lavanya, Manjunath Kamath S, Subha Krishna Rao, P. Rajapriya, Shantanu Patil, S. Sundaresan, Journal of Drug Delivery Science and Technology, Volume 74, 2022.

Mahima Sharma and Sony Varghese IEEE Explore Integrated STEM Education Conference (ISEC), Princeton, NJ, USA, 2022, pp. 391-394.

Gobi Saravanan Kaliaraj, DK Shanmugam, A Dasan, KKA Mosas, Gels 9 (3), 260. (2023).

V Vishwakarma, Gobi Saravanan Kaliaraj, KK Amirtharaj Mosas, Coatings 13 (1), 69 (2022).

S Kathiravan, Gobi Saravanan Kaliaraj, AM Kamalan Kirubaharan, Ravi Ranjan Kumar, Ceramics International, 48, 24, 36012-36020 (2022).

V Vishwakarma, Gobi Saravanan Kaliaraj, AMK Kirubaharan, Coatings 12 (10), 1525 (2022).

DK Shanmugam, Y Madhavan, A Manimaran, Gobi Saravanan Kaliaraj, KG Mohanraj, Gels 9 (1), 22 (2022)

A Ramadoss, A Tripathy, A Mohanty, N Swain, Gobi Saravanan Kaliaraj, SZ Noby, Vacuum, 111848 (2022).

Sony Varghese and K. Hariharan “Lithium sulfate thin film by electron beam evaporation” Published online in Material Today Proceedings 2023.

Funded Projects:

Superhydrophobic Coated 3D Printed Temporary Implants - A Boon to the Patients (File No: SP/YO/2021/2499) Scheme for Young Scientists and Technologists (SYST), Department of Science and Technology (DST), Govt. of India. (PI Name: K. Gobi Saravanan; Sanctioned amount: Rs. 21,04,000). Status: Provisionally approved.

Programs:

DST sponsored STUTI Program

Hands on training program:

Open House Program:

Training Program (For external)

Contact Details

MAKERSPACE Lab

Sathyabama centre for Advanced Studies

Sathyabama Institute of Science and Technology Chennai - 600119. Tamilnadu

Phone: +91-44-2450 3065

Email: [email protected]